What makes lightweight materials so special? Lightweight materials are game-changers in many industries. They offer strength without the bulk, making them ideal for everything from cars to airplanes. Imagine a car that uses less fuel because it's lighter or a plane that can carry more cargo due to reduced weight. These materials also play a crucial role in sports equipment, allowing athletes to perform better. Lightweight materials are not just about being light; they also bring durability and efficiency. Whether it's carbon fiber, aluminum, or advanced composites, these materials are shaping the future. Ready to learn more? Let's dive into 20 fascinating facts about these incredible materials!

What Are Lightweight Materials?

Lightweight materials are essential in various industries due to their low density and high strength. They are used to reduce weight while maintaining or improving performance.

-

Aluminum is one of the most common lightweight materials. It is used in everything from soda cans to airplane parts due to its strength and low weight.

-

Titanium is another lightweight material known for its high strength-to-weight ratio. It is often used in aerospace and medical applications.

-

Magnesium is the lightest structural metal available. It is used in automotive and aerospace industries to reduce weight and improve fuel efficiency.

-

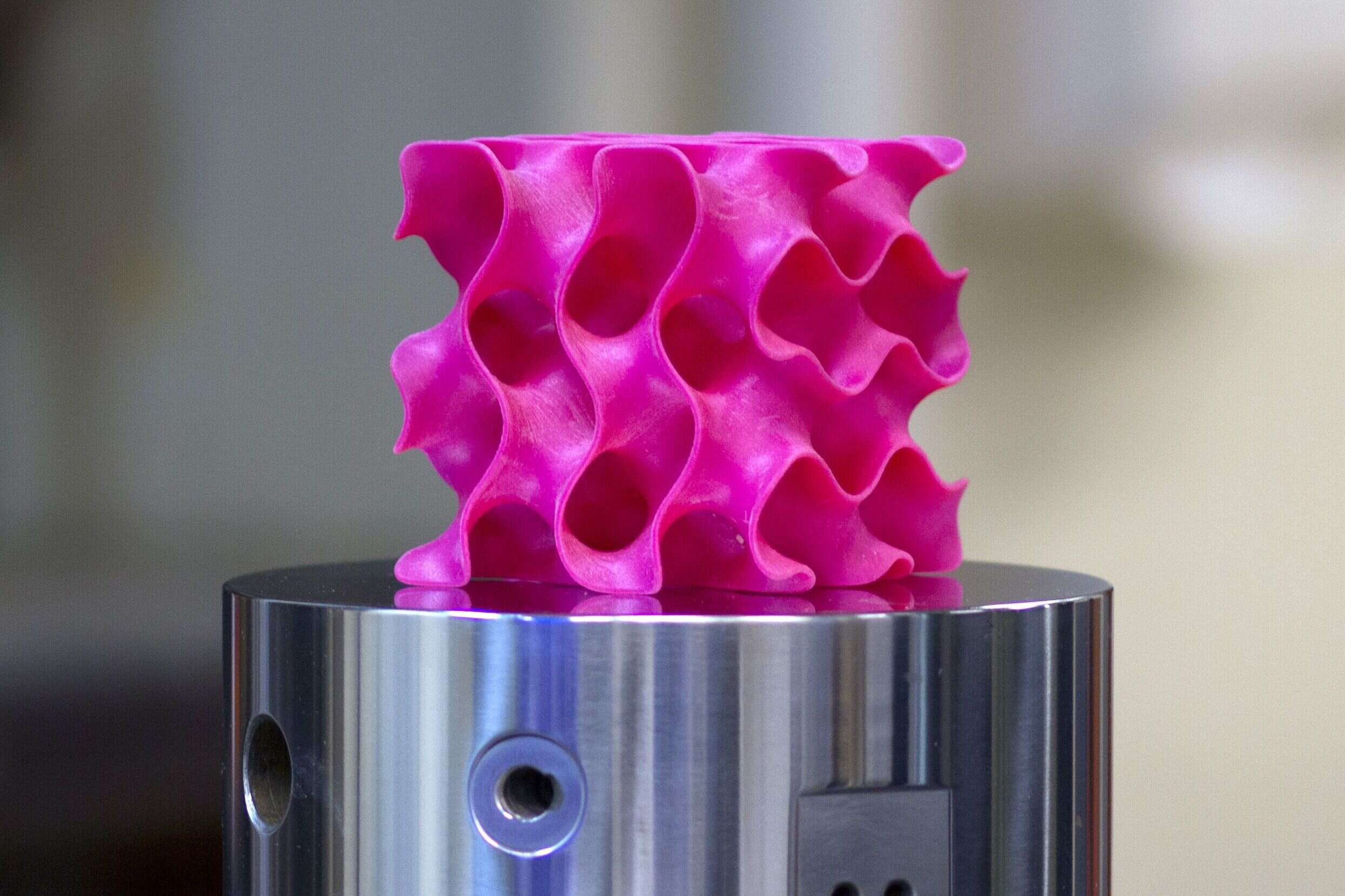

Carbon Fiber is a strong, lightweight material made from thin strands of carbon. It is used in high-performance sports equipment, aerospace, and automotive industries.

-

Kevlar is a synthetic fiber known for its high tensile strength-to-weight ratio. It is used in bulletproof vests, helmets, and other protective gear.

Benefits of Lightweight Materials

Using lightweight materials offers numerous advantages, particularly in industries where weight reduction is crucial.

-

Fuel Efficiency improves significantly in vehicles and aircraft when lightweight materials are used. Less weight means less fuel consumption.

-

Performance is enhanced in sports equipment made from lightweight materials. Athletes can perform better with lighter gear.

-

Durability is often higher in lightweight materials like carbon fiber and Kevlar, which are resistant to wear and tear.

-

Environmental Impact is reduced when using lightweight materials. Lower fuel consumption leads to fewer emissions.

-

Cost Savings can be achieved over time with lightweight materials. Although they may be more expensive initially, the savings in fuel and maintenance can be substantial.

Applications of Lightweight Materials

Lightweight materials are used in a wide range of applications, from everyday items to advanced technology.

-

Automotive Industry uses lightweight materials to make cars more fuel-efficient and environmentally friendly.

-

Aerospace Industry relies on lightweight materials to build aircraft that can fly longer distances with less fuel.

-

Sports Equipment such as bicycles, tennis rackets, and golf clubs are often made from lightweight materials to improve performance.

-

Medical Devices like prosthetics and implants are made from lightweight materials to ensure comfort and functionality.

-

Construction uses lightweight materials like aluminum and composite panels to build structures that are strong yet easy to handle.

Challenges of Lightweight Materials

Despite their benefits, lightweight materials also present some challenges.

-

Cost can be a barrier, as lightweight materials like carbon fiber and titanium are often more expensive than traditional materials.

-

Manufacturing processes for lightweight materials can be complex and require specialized equipment.

-

Recycling lightweight materials can be difficult. For example, carbon fiber is not as easily recyclable as aluminum.

-

Availability of some lightweight materials can be limited, affecting their widespread adoption.

-

Performance Trade-offs may occur. While lightweight materials are strong, they may not always offer the same level of durability as heavier materials in certain applications.

Final Thoughts on Lightweight Materials

Lightweight materials have revolutionized industries, offering strength without the bulk. Carbon fiber and aluminum are game-changers in automotive and aerospace sectors, reducing weight and boosting fuel efficiency. Titanium stands out in medical implants due to its biocompatibility. Magnesium alloys, although less common, provide excellent strength-to-weight ratios. Graphene, a newer material, promises future advancements with its incredible strength and conductivity. These materials not only enhance performance but also contribute to sustainability by reducing energy consumption. Understanding their properties and applications helps us appreciate their impact on modern technology. From sports equipment to space exploration, lightweight materials are integral to innovation. Keep an eye on emerging materials like metal foams and nanotubes, which could further transform industries. Embracing these advancements ensures we stay ahead in a world that values efficiency and sustainability.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.